Bigelow Boiler Co. Redux: 150 Years at 198 River Street

Paul Wu (2019)

History

On the 150th anniversary of the Bigelow Boiler Company Buildings, it’s important to reconnect to its past and speculate on its potential for the future. Bigelow started construction on the industrial complex in 1869, and it was New Haven’s most valuable industrial giant. Bigelow Boilers have been sold globally, and they all originated from the lot on 198 River St. Bigelow, however, was a victim of its own times. While the buildings were abandoned in the 1980s, the facades have, for the most part, managed to stay standing. Since then, the buildings have fallen into disrepair. The building on the corner is currently undergoing an extensive adaptive reuse restoration, but this was at the cost of the small infill building adjoining it. From multiple interviews, it was discovered that most of the structures have fallen into critical damaged - being too weak for an adaptive reuse effort. These facades have an immense presence in New Haven, and to lose them would be to lose a little of the city itself. I am proposing a preservation effort of the facades through a series of EPA grants for the brownfield assessment and cleanup as well as facade restoration grants. Additionally, the developments would be pushed within the lot - keeping the space immediately behind the facades open for public use.

Colonial days Connecticut, third smallest of all the states, has been the fulcrum on which much of this nation’s productive power has been raised above all the rest of the world.

There is scarcely an American industry that has not been shaped by the marvelous machines and methods devised by skillful, imaginative, determined and resourceful Connecticut men.”

There is scarcely an American industry that has not been shaped by the marvelous machines and methods devised by skillful, imaginative, determined and resourceful Connecticut men.”

- “Connecticut Industry; October 1958”

192 River St. aerial image

192 River St. aerial image

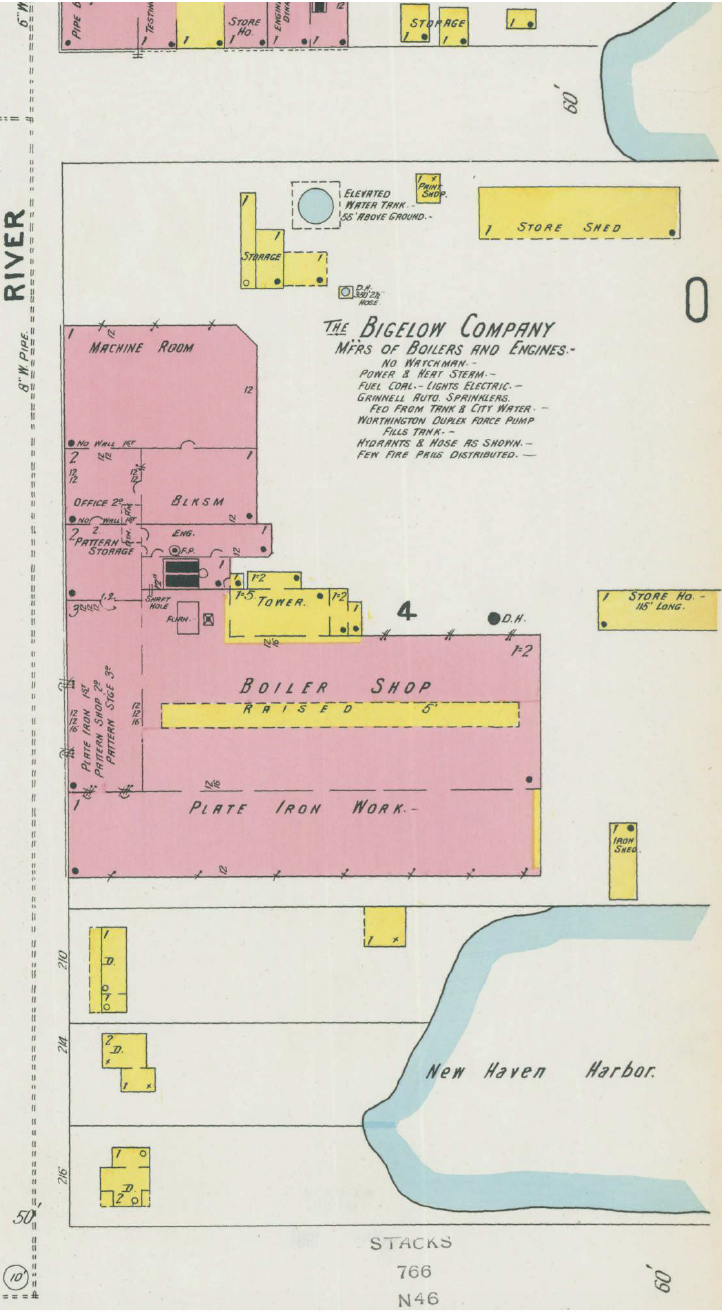

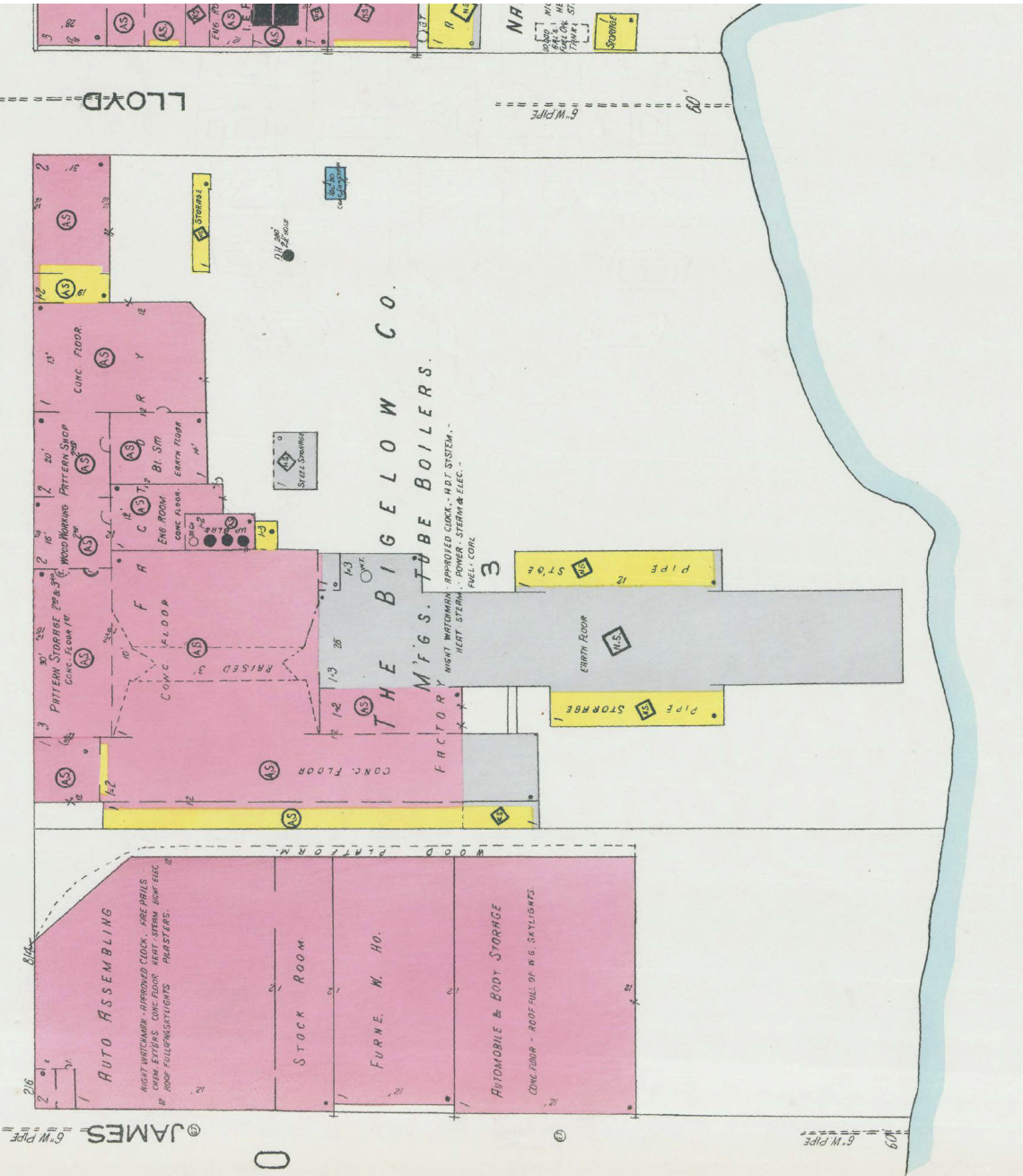

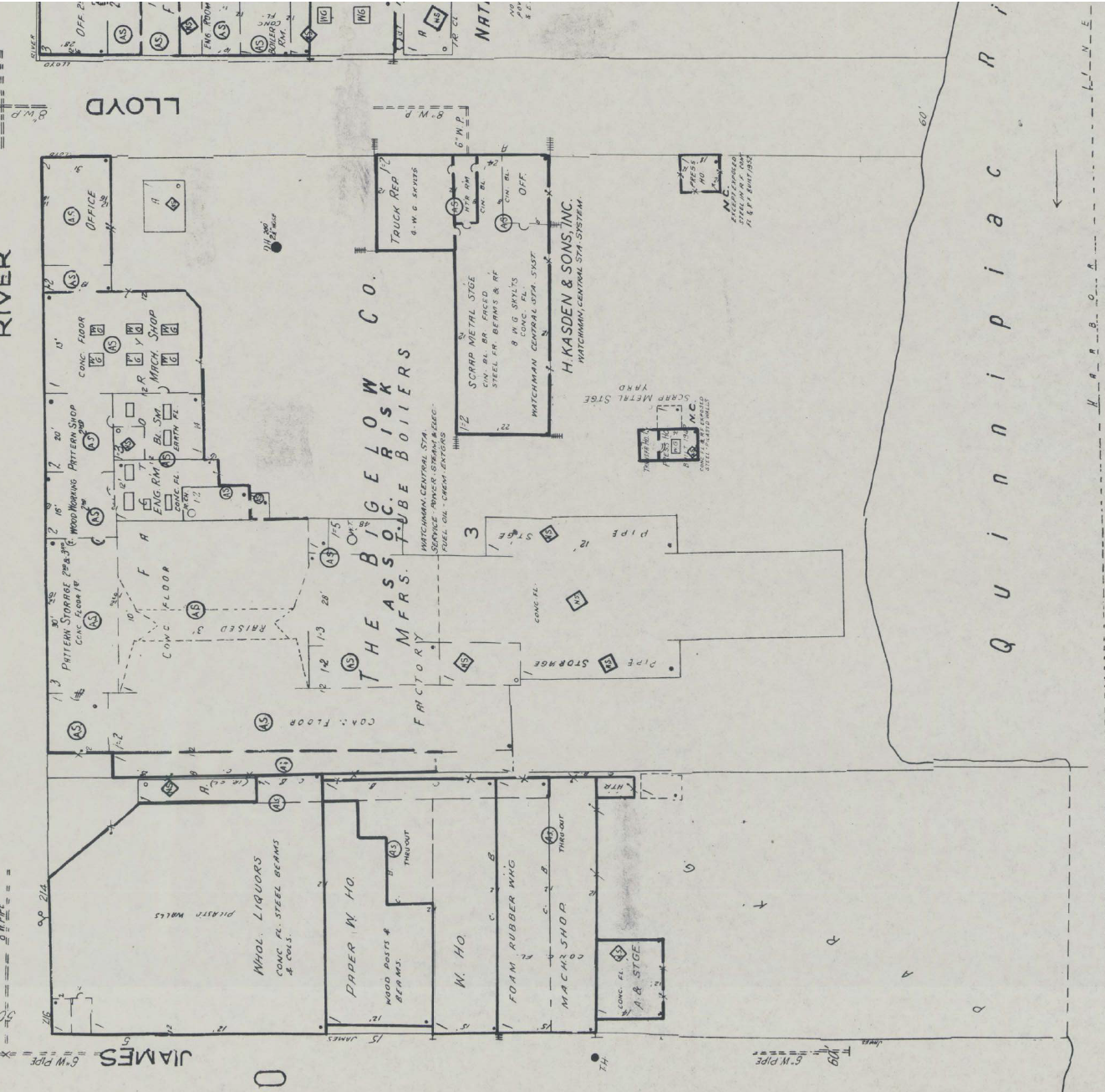

Left to Right: 1901 Sanborn Map, 1924 Sanborn Map, 1973 Sanborn Map.

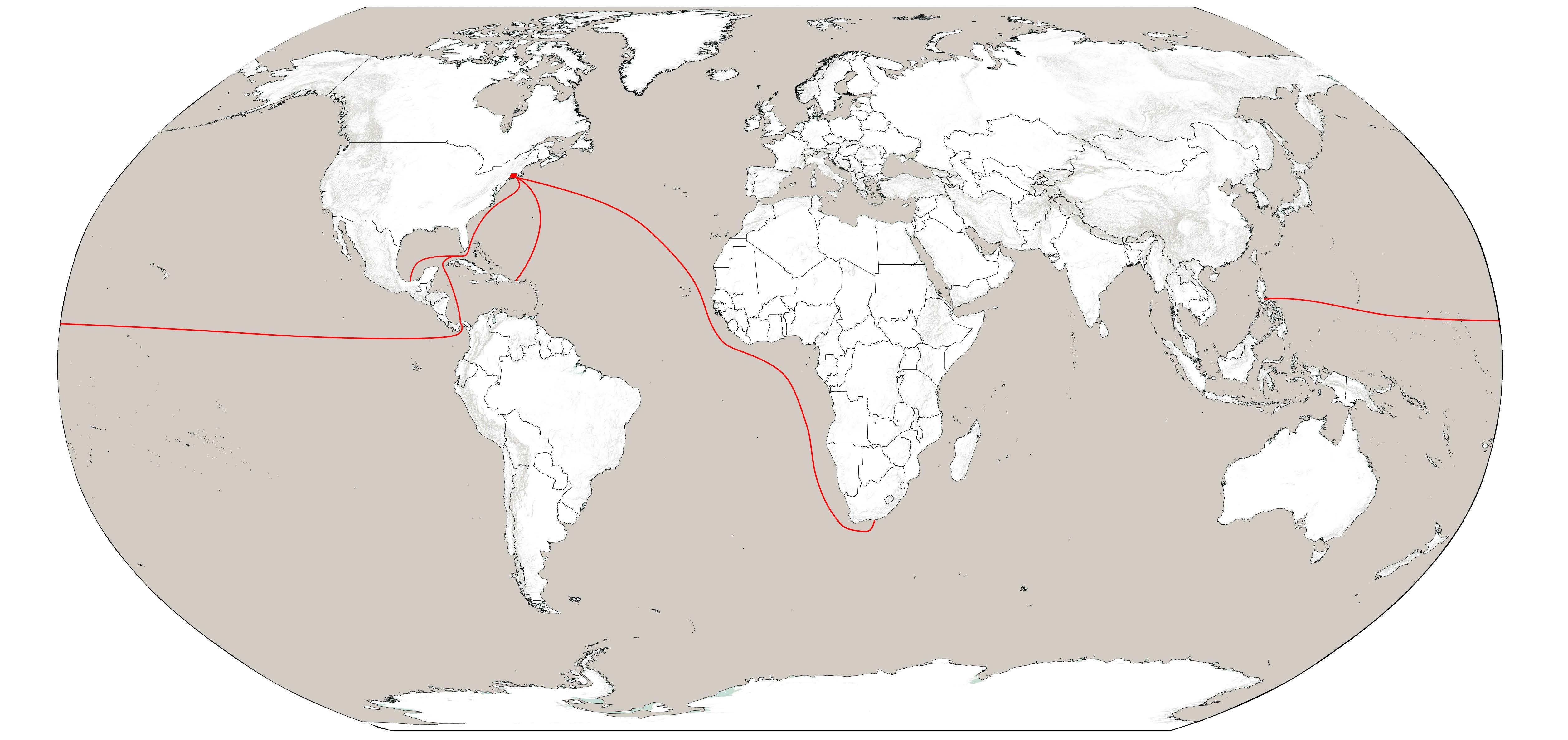

“Largest packaged boiler” shipping path

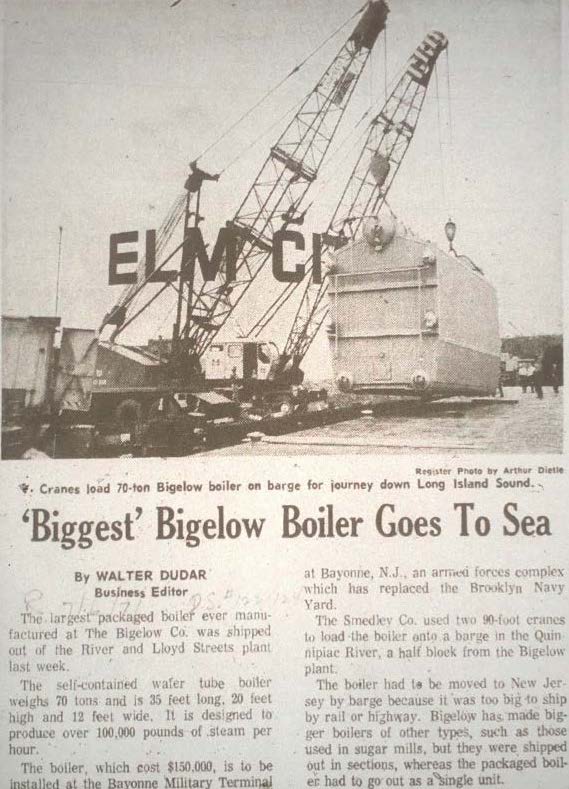

“The largest packaged boiler ever manufactured at The Bigelow Co. was shipped out of the River and Lloyd Streets plant last week.

The self-contained water tube boiler weighs 70 tons and is 35 feet long, 20 feet high and 12 feet wide. It is designed to produce over 100,000 pounds of steam per hour.

The boiler, which cost $150,000, is to be installed at the Bayonne Military Terminal at Bayonne, N.J., an armed forces complex which has replaced the Brooklyn Navy Yard.

The Smedly Co. used two 90-foot cranes to load the boiler onto a barge in the Quinnipiac River, a half block from the Bigelow plant.

The boiler had to be moved to New Jersey by barge because it was too big to ship by rail or highway. Bigelow has made bigger boilers of other types, such as those used in sugar mills, but they were shipped out in sections, whereas the packaged boiler had to go out as a single unit.”

The self-contained water tube boiler weighs 70 tons and is 35 feet long, 20 feet high and 12 feet wide. It is designed to produce over 100,000 pounds of steam per hour.

The boiler, which cost $150,000, is to be installed at the Bayonne Military Terminal at Bayonne, N.J., an armed forces complex which has replaced the Brooklyn Navy Yard.

The Smedly Co. used two 90-foot cranes to load the boiler onto a barge in the Quinnipiac River, a half block from the Bigelow plant.

The boiler had to be moved to New Jersey by barge because it was too big to ship by rail or highway. Bigelow has made bigger boilers of other types, such as those used in sugar mills, but they were shipped out in sections, whereas the packaged boiler had to go out as a single unit.”

“Largest packaged boiler” shipping path

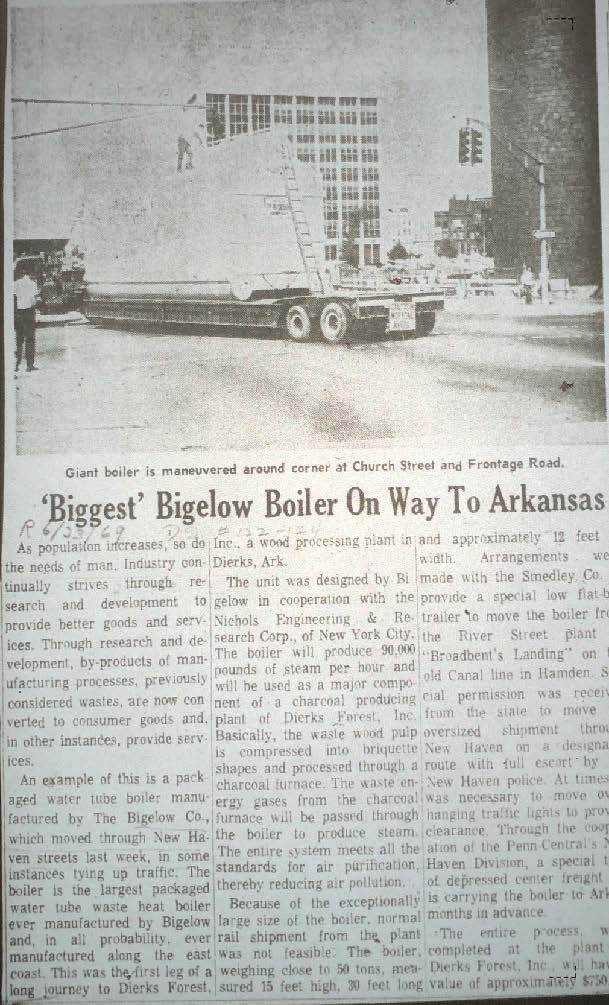

“The largest packaged boiler ever manufactured at The Bigelow Co. was shipped out of the River and Lloyd Streets plant last week.

The self-contained water tube boiler weighs 70 tons and is 35 feet long, 20 feet high and 12 feet wide. It is designed to produce over 100,000 pounds of steam per hour.

The boiler, which cost $150,000, is to be installed at the Bayonne Military Terminal at Bayonne, N.J., an armed forces complex which has replaced the Brooklyn Navy Yard.

The Smedly Co. used two 90-foot cranes to load the boiler onto a barge in the Quinnipiac River, a half block from the Bigelow plant.

The boiler had to be moved to New Jersey by barge because it was too big to ship by rail or highway. Bigelow has made bigger boilers of other types, such as those used in sugar mills, but they were shipped out in sections, whereas the packaged boiler had to go out as a single unit.”

The self-contained water tube boiler weighs 70 tons and is 35 feet long, 20 feet high and 12 feet wide. It is designed to produce over 100,000 pounds of steam per hour.

The boiler, which cost $150,000, is to be installed at the Bayonne Military Terminal at Bayonne, N.J., an armed forces complex which has replaced the Brooklyn Navy Yard.

The Smedly Co. used two 90-foot cranes to load the boiler onto a barge in the Quinnipiac River, a half block from the Bigelow plant.

The boiler had to be moved to New Jersey by barge because it was too big to ship by rail or highway. Bigelow has made bigger boilers of other types, such as those used in sugar mills, but they were shipped out in sections, whereas the packaged boiler had to go out as a single unit.”

Global Reach

“Bigelow witnessed and was part of America’s industrial renaissance. It was among the original 47 subscribers to telephone service. It is New Haven’s oldest manufacturing Company in point of continuous solvency. And after a century and a quarter it continues to be a vigorous, forward-looking component of the American industrial picture.

In reality, Bigelow, which of course does not mass-produce its famous industrial and institutional boilers, is an integral part of the Free World’s economy. Its boilers power mines in South Africa, oil wells and pipelines in Mexico, sugar mills in the West Indies and the coconut shredding plant of Peter Paul, Inc. in the faraway Philippines.

Their boilers are also to be found in California wineries and distilleries, in such widely separated Universities as Yale and Leland Stanford, in factories, foundries and electric power plants and in Madison Square Garden.”

- “Connecticut Industry; October 1958”

In reality, Bigelow, which of course does not mass-produce its famous industrial and institutional boilers, is an integral part of the Free World’s economy. Its boilers power mines in South Africa, oil wells and pipelines in Mexico, sugar mills in the West Indies and the coconut shredding plant of Peter Paul, Inc. in the faraway Philippines.

Their boilers are also to be found in California wineries and distilleries, in such widely separated Universities as Yale and Leland Stanford, in factories, foundries and electric power plants and in Madison Square Garden.”

- “Connecticut Industry; October 1958”

Site Analysis

Current state, 2019.

Precedent for Reuse

Max Family Garden in Brooklyn near DUMBO.

Reuse Plan

Current State:

Highlighted is being restored, solid line means intact, dashed means intact but critically unsound, and dotted lines no longer exist.

Highlighted is being restored, solid line means intact, dashed means intact but critically unsound, and dotted lines no longer exist.

Brownfield Assessment:

As the site of heavy industry, the lot is unfortunately faced with metal contamination. An EPA grant can fund the initial assessment.

As the site of heavy industry, the lot is unfortunately faced with metal contamination. An EPA grant can fund the initial assessment.

Facade Preservation:

The deteriorating structures are carefully dismantled in order to preserve the facades. The exterior walls should be structurally sound on their own, but additional bracing may be necessary. As a work of historic preservation, the facade is eligible for federal facade restoration grants.

The deteriorating structures are carefully dismantled in order to preserve the facades. The exterior walls should be structurally sound on their own, but additional bracing may be necessary. As a work of historic preservation, the facade is eligible for federal facade restoration grants.

Brownfield Remediation:

Concurrent with the facade preservation is the brownfield remediation, which is potentially funded by the EPA. The old footprints of the buildings are cleaned and covered. A layer of boardwalks line the perimeter.

Concurrent with the facade preservation is the brownfield remediation, which is potentially funded by the EPA. The old footprints of the buildings are cleaned and covered. A layer of boardwalks line the perimeter.

Development:

The remaining buildings are restored and additional construction takes place within the lot in order to preserve public access through the facades.

The remaining buildings are restored and additional construction takes place within the lot in order to preserve public access through the facades.

Inhabitation:

198 River St. has the potential to become a public commons. With public access from the streets, views towards the Long Island Sound, and potential collaborations with community organizations within the area, the Bigelow Company’s legacy will remain intact for future generations to appreciate.

198 River St. has the potential to become a public commons. With public access from the streets, views towards the Long Island Sound, and potential collaborations with community organizations within the area, the Bigelow Company’s legacy will remain intact for future generations to appreciate.

Facade:

The freestanding facade acts as a screen opening to a new public space beyond.

The freestanding facade acts as a screen opening to a new public space beyond.